Industrial sectors in India are rapidly evolving, and the demand for efficient drying technologies is on the rise. Flash dryers have become one of the most sought-after solutions in manufacturing, as they offer quick and energy-efficient drying. Whether it’s minerals, chemicals, or food products, flash dryers ensure consistent results, improving productivity across industries. Here’s a closer look at Top Industrial Flash Dryer In India.

What Are Industrial Flash Dryers?

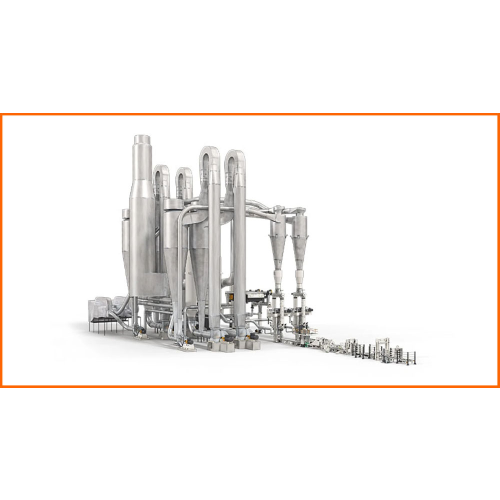

Industrial flash dryers reduce moisture content in materials quickly and efficiently. These systems use hot air or gas to dry fine powders, granules, or fluids within seconds. The process disperses the material into heated air, allowing rapid evaporation. This swift method avoids overheating and maintains the material’s quality.

Key Features of Top Industrial Flash Dryers

Modern flash dryers stand out due to their advanced features. Below are some of their most vital characteristics, explained with a seamless flow.

- Energy Efficiency

To begin with, flash dryers excel in energy conservation. Unlike traditional drying methods, they consume significantly less energy. Additionally, their optimized design maximizes heat utilization, which helps keep operational costs low. - High Throughput

Furthermore, these dryers demonstrate exceptional performance at an industrial scale. They efficiently handle large volumes of materials, ensuring consistent drying without delays. This reliability proves crucial when industries need to meet tight production timelines. - Compact Design

Lastly, their smart, compact design is another game-changer. Despite their ability to manage high volumes, they require minimal space. As a result, industries can easily integrate them into existing setups without worrying about space constraints.

Benefits of Using Industrial Flash Dryers

Industrial flash dryers offer several significant advantages for manufacturers in India. To start with, their remarkable speed and efficiency greatly enhance productivity. By processing materials quickly, they enable businesses to meet increasing market demands without any delays.

Additionally, the advanced technology used in flash dryers ensures that heat-sensitive materials dry without any degradation. This not only maintains the integrity of the materials but also ensures superior output quality, which is crucial for achieving customer satisfaction.

Why Flash Dryers Are the Future of Drying Technology

Industrial flash dryers are revolutionizing manufacturing processes with their exceptional efficiency, flexibility, and durability. To begin with, they tackle key challenges such as high energy consumption, ensuring operations are more sustainable. Additionally, their ability to maintain product quality while scaling up production makes them an invaluable asset for industries.

From food processing units to chemical plants, the advantages of flash drying technology extend across various sectors. For instance, they provide faster drying solutions without compromising material integrity, which is essential for sensitive goods. Furthermore, their adaptability allows businesses to integrate them into diverse workflows seamlessly.